The 9-Second Trick For 24hr Media

The 9-Second Trick For 24hr Media

Blog Article

Fascination About 24hr Media

Table of ContentsNot known Factual Statements About 24hr Media An Unbiased View of 24hr MediaThe Definitive Guide for 24hr MediaExamine This Report about 24hr MediaA Biased View of 24hr Media

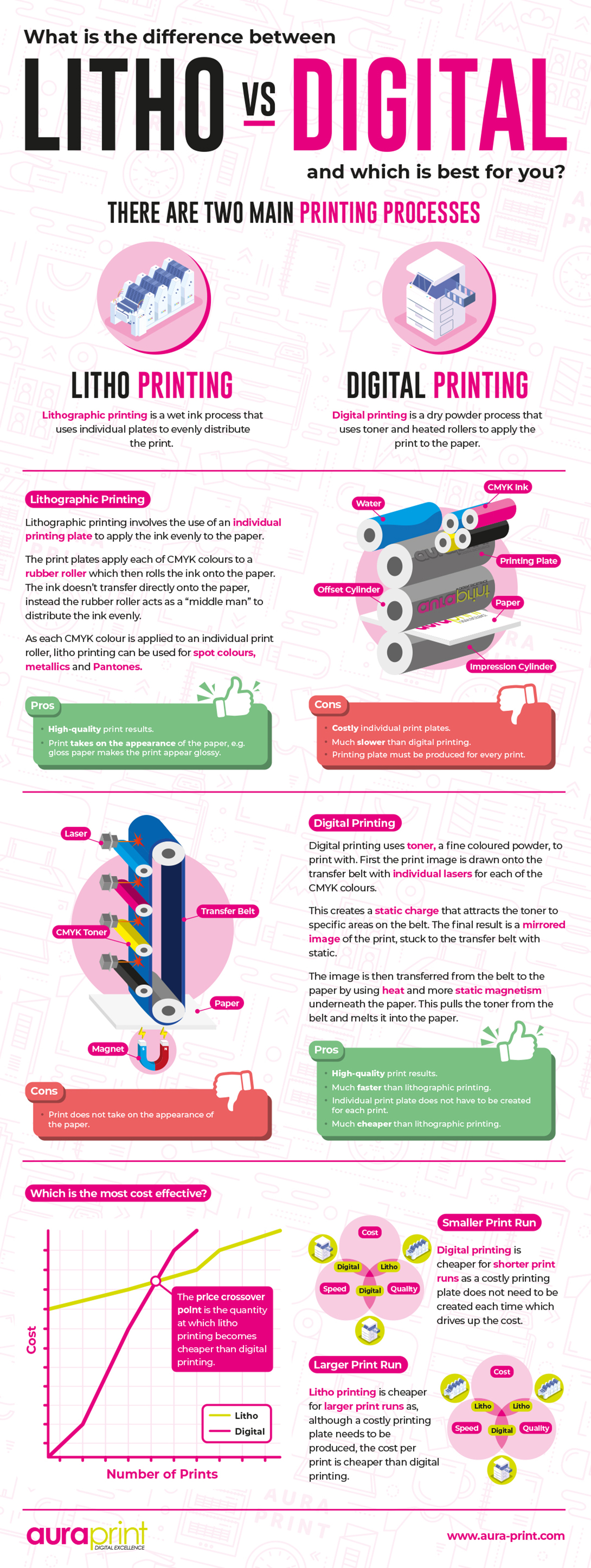

Developments in print innovation are altering the communications playing field when it concerns quality, price and cutting-edge capacities. Countered printing and electronic printing are the major processes through which print tasks are embarked on both using four-color printing methods. Each option has its benefits, using different techniques to fulfill the requirements of diverse manufacturing jobs.

Typically, this has actually been the most constant technique for exactly maintaining shade suits, making it suitable for print runs that only need static printing such as pre-printed types, sales brochures, flyers, business cards, and bulk postcard mailings. Due to the static nature of litho printing, it is not suitable for variable print pieces that will be sent by mail to specific recipients such as statements, letters, and individualized postcards.

How 24hr Media can Save You Time, Stress, and Money.

The newest innovations in print innovation are aiding to bring numerous of countered's advantages into the electronic printing world genuinely changing the face of modern printing! There are some crucial differences between Offset Printing and Digital Printing.

Today's electronic print tools is among the most sophisticated on the market. Right here are several of the greatest advantages of utilizing electronic printing: control the electronic print space, with full-color printing completed in one procedure and seamlessly printed directly from a print data. Without an extensive set up process, the calibration time of a particular task is reduced, adding to quicker print time and total delivery.

The inkjet printing process has helped to transform the market along with the top quality and rate of the result. The latest inkjet technology can print on conventional balanced out supplies with boring, silk, and shiny surfaces. High-quality digital print coupled with software-managed color management practices includes optimum worth to print pieces and makes production processes more reliable than offset.

Getting The 24hr Media To Work

(http://www.place123.net/place/24%CA%B0%CA%B3media-cape-town-south-africa)

Eco-friendly and naturally degradable inks and printer toners are additionally readily available for even more sustainable printing. Digital print additionally removes the demand to wash plates or useful source blankets with dangerous chemicals at the end of the printing procedure.

Variable information helps businesses reach their exact consumers and target market with uniquely-created and customized content. As innovation improves, the high quality of digital printing has become second-to-none, with higher information, shade match capacities and total accuracy. Without the demand to wash plates or utilize excess ink, digital printing is likewise much less inefficient and typically a lot more ecologically pleasant.

("flexo"), entail several make-ready actions to move an original photo to a substrate.

24hr Media Things To Know Before You Get This

Digital printing, with fewer relocating items, is much more agile than offset in this respect.

Minimized set-up time conserves money on the front end. And because these are not massive bulk orders, smaller businesses can afford to print without having to fulfill the greater and more costly print limits of typical printing.

Make certain you work together with a printing and product packaging companion that has the right certifications. While eleventh-hour printing and personalization are a huge benefit, digital may not constantly be the ideal method for you. For example, balance out printing has the benefit of cost-effectiveness with huge print runs, specifically those with advanced decorative effects and specialty finishes.

Excitement About 24hr Media

Lithographic presses make use of 2 print platesa positive and a negativeto transfer top quality color graphics onto an ideal substratum. The positive plate, with its smooth surface area, brings in oil-based inks and pushes back water. In comparison, the negative plate, with its harsh structure, absorbs water and repels oil. Rubber rollers are after that utilized to move the picture from the plate to the corrugated surface area.

Corrugated paper can often show to be a tough surface to publish on, but Litho prints to a different surface and is then laminated flooring to it, making it simple to publish premium images. It can be very regular, even for long terms. The much more you publish, the cheaper the expenses come to be for Litho.

If you have enough time and budget plan, and a huge volume of a single style, after that there should not be an issue. What Litho doesn't provide you is specifically what Digital does, personalization. Extra on that later. Costly established up Longer turn-around No Variable Information Printing Smaller sized color gamut, colors can be much less intense Digital printing is the procedure of printing digital photos straight onto the corrugated substrate using a single-pass, direct-to-corrugate method - Stickers.

Report this page